The Future of India’s Semiconductor Sector: Challenges and Opportunities

-

by nagendra singh

- 21

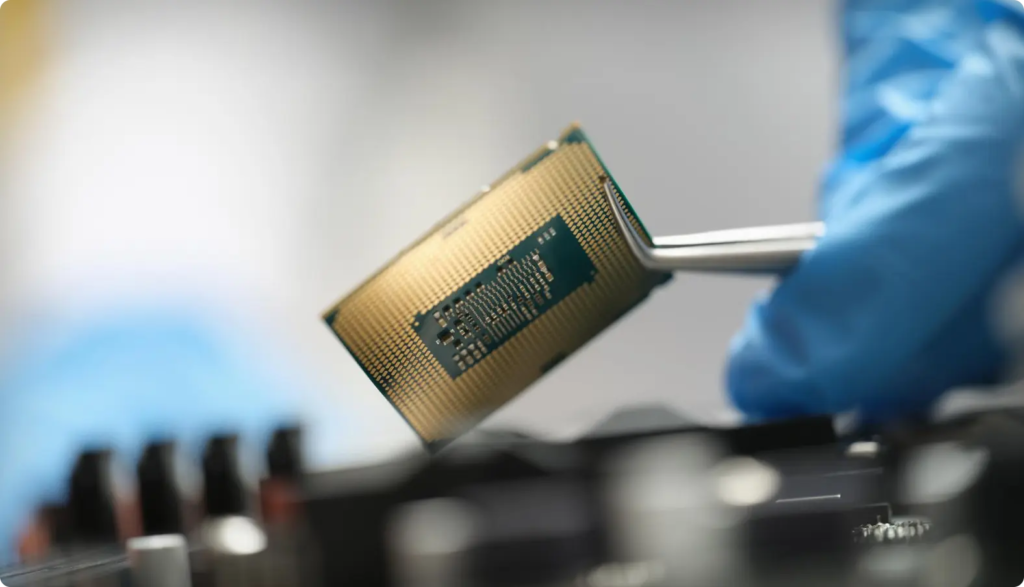

The Indian semiconductor industry is emerging as a critical pillar in the country’s ambition to become a global technology hub.

Semiconductors, often referred to as the “brain” of modern electronics, power everything from smartphones to electric vehicles, and their strategic importance cannot be overstated.

Recognizing this, the Indian government has launched ambitious initiatives to foster the growth of this sector, aiming to reduce reliance on imports, boost domestic manufacturing, and position India as a key player in the global semiconductor supply chain.

This blog post explores the current state of India’s semiconductor industry and the government’s efforts to propel its growth.

The Importance of Semiconductors in India

India’s electronics market is one of the largest in the world, driven by increasing demand .For consumer electronics, telecommunications, automotive technologies, and emerging fields like artificial intelligence (AI) and the Internet of Things (IoT).

However, the country heavily relies on imported semiconductors, primarily from countries like Taiwan, South Korea, and China.

In 2023, India imported semiconductors worth over $20 billion annually, highlighting a significant dependency that poses both economic and strategic risks, especially amid global supply chain disruptions.

Developing a robust domestic semiconductor ecosystem is crucial for India’s self-reliance (“Atmanirbhar Bharat”) and national security. A strong semiconductor industry can also create high-skilled jobs, drive innovation, and contribute significantly to the economy.

The Indian government has recognized these imperatives and is taking bold steps to build a competitive semiconductor manufacturing and design ecosystem.

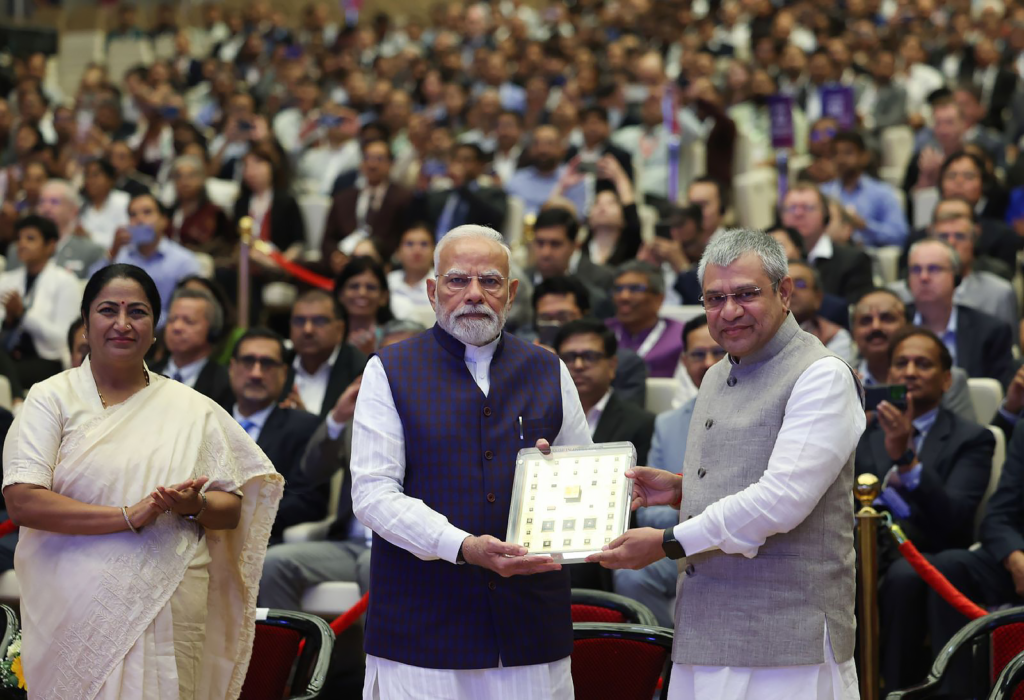

Government Initiatives to Boost the Semiconductor Industry

The Indian government has rolled out several policies and financial incentives to catalyze the growth of the semiconductor industry. Below are the key initiatives driving this transformation:

1. India Semiconductor Mission (ISM)

Launched in 2021 under the Ministry of Electronics and Information Technology (MeitY), the India Semiconductor Mission is the cornerstone of India’s semiconductor strategy.

The ISM aims to build a comprehensive ecosystem for semiconductor design, fabrication, and testing. Key objectives include:

- Attracting Investments: The ISM facilitates partnerships with global semiconductor giants and encourages foreign direct investment (FDI) in chip manufacturing and design.

- Skill Development: The mission focuses on creating a skilled workforce through specialized training programs and collaborations with academic institutions.

- R&D Support: It promotes research and development in semiconductor technologies to foster innovation and indigenous intellectual property (IP) creation.

2. Production-Linked Incentive (PLI) Scheme

The government introduced a $10 billion (approximately ₹76,000 crore) PLI scheme in December 2021 to incentivize semiconductor and display manufacturing in India. This scheme provides financial subsidies of up to 50% of project costs for setting up semiconductor fabrication units (fabs), assembly, testing, marking, and packaging (ATMP) facilities, and display manufacturing units. The PLI scheme has attracted interest from global players like Taiwan’s TSMC and domestic companies like Vedanta and Tata Group.

3. Design-Linked Incentive (DLI) Scheme

To strengthen India’s semiconductor design ecosystem, the government launched the DLI scheme, which offers financial support and infrastructure access to domestic companies, startups, and academic institutions engaged in chip design. This initiative aims to nurture a vibrant design ecosystem, enabling Indian firms to develop chips for applications like 5G, AI, and automotive electronics.

4. Infrastructure Development

The government is establishing dedicated semiconductor hubs and industrial parks to provide state-of-the-art infrastructure for chip manufacturing and testing. For instance, Dholera in Gujarat is being developed as a semiconductor manufacturing hub, equipped with advanced facilities, reliable power, and water supply to attract global investors.

5. Public-Private Partnerships and Global Collaborations

The Indian government is actively collaborating with global semiconductor leaders to bring cutting-edge technology and expertise to India. Notable developments include:

- Micron Technology: In 2023, US-based Micron Technology announced a $2.75 billion investment to set up an ATMP facility in Gujarat, supported by incentives from the central and state governments.

- Tata Group: Tata is exploring partnerships to establish semiconductor fabrication plants, signaling strong domestic participation.

- International Alliances: India has signed MoUs with countries like the US, Japan, and the EU to foster technology transfer, joint research, and supply chain resilience.

6. Policy Reforms and Ease of Doing Business

To create a conducive environment for semiconductor investments, the government has streamlined regulatory processes, offered tax breaks, and provided land subsidies. Additionally, initiatives like the “Make in India” campaign and reforms in FDI policies have made it easier for global companies to set up operations in India.

Recent Milestones in India’s Semiconductor Journey

India’s push for semiconductor self-reliance has already yielded promising results:

- Micron’s Gujarat Facility: Micron’s ATMP plant, expected to be operational by late 2024, will create thousands of jobs and produce chips for both domestic and global markets.

- Vedanta-Foxconn Partnership: In 2022, Vedanta Group and Taiwan’s Foxconn announced a $19.5 billion joint venture to set up a semiconductor fab and display manufacturing unit in Gujarat, although progress has faced some delays.

- R&D Advancements: Indian startups and institutions, such as the Indian Institute of Science (IISc) and IIT Bombay, are developing indigenous chip designs for applications like 5G and defense.

- Semiconductor Training Programs: Over 20,000 engineers and technicians are being trained annually through government-backed programs to meet the industry’s skill demands.

Challenges and the Road Ahead

Despite the progress, India’s semiconductor industry faces several challenges:

- High Capital Costs: Setting up a semiconductor fab requires investments of $5-20 billion, making it a capital-intensive endeavor.

- Technology Gaps: India lags in advanced process nodes (e.g., 5nm or 3nm chips), which are critical for cutting-edge applications.

- Supply Chain Dependencies: Raw materials like high-purity silicon and rare gases are still imported, requiring a robust supply chain ecosystem.

- Talent Shortage: While training programs are underway, scaling up a skilled workforce to meet global standards remains a challenge.

To address these hurdles, the government is focusing on long-term strategies, such as increasing R&D funding, fostering public-private partnerships, and building a resilient supply chain. By 2030, India aims to have multiple operational fabs and a thriving design ecosystem, contributing significantly to the global semiconductor market, projected to reach $1 trillion by the end of the decade.

Conclusion

The Indian semiconductor industry is at a pivotal moment, with the government’s proactive policies and incentives laying the foundation for a transformative journey. Through initiatives like the India Semiconductor Mission, PLI and DLI schemes, and strategic global partnerships, India is steadily reducing its dependence on imports and carving a niche in the global semiconductor landscape. While challenges remain, the government’s commitment to fostering innovation, infrastructure, and talent development positions India to become a major player in this critical industry. As these efforts gain momentum, the dream of a self-reliant, technologically advanced India is closer than ever.

Also Read :

Learn 80% of Perplexity AI in Under 5 Minutes

The Spotify Model Explained: How Teams Can Scale Agile with Autonomy and Innovation

Trump’s Outsourcing Crackdown: A Game-Changer for India’s IT Industry and America’s Tech Landscape

visit :

http://wekipediahttp://en.wikipedia.org

The Indian semiconductor industry is emerging as a critical pillar in the country’s ambition to become a global technology hub. Semiconductors, often referred to as the “brain” of modern electronics, power everything from smartphones to electric vehicles, and their strategic importance cannot be overstated. Recognizing this, the Indian government has launched ambitious initiatives to foster…

The Indian semiconductor industry is emerging as a critical pillar in the country’s ambition to become a global technology hub. Semiconductors, often referred to as the “brain” of modern electronics, power everything from smartphones to electric vehicles, and their strategic importance cannot be overstated. Recognizing this, the Indian government has launched ambitious initiatives to foster…